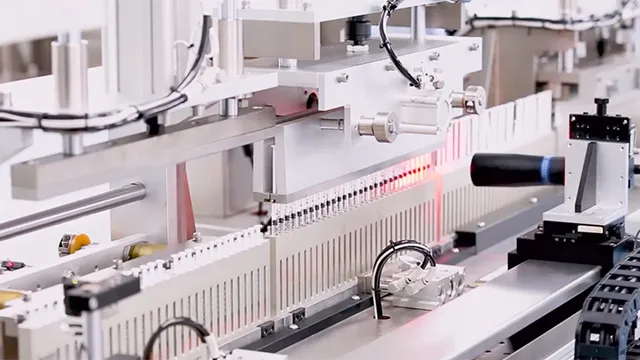

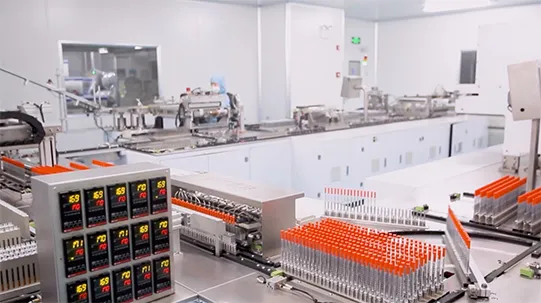

Yeso-Med operates a 11,000 square meter facility, producing an impressive range of medical devices each year. Our production capabilities include 600 million auto-disable syringes, 500 million safety syringes, 4 million high-pressure syringes, 200 million insulin syringes, 400 million standard syringes, 1 billion medical masks, and 2 million sets of surgical instruments. We adhere to strict quality management standards, holding ISO13485-2016 and ISO9001-2015 certifications, and passed US FDA audits in July 2014 and September 2017 with no defects.